I was lacking a huge amount of clutch and brake fluid. So I topped up and had another look today and the area around the brake master cylinder is damp. The paint was flakey before and it's not going to get much better with fresh fluid pouring all over it! My plan is to rebuild (and possibly replace) both cylinders. I had previously replaced all brake and clutch parts except the clutch pipe and the master cylinders so I guess its about time! I thought I'd also take the time to repaint the bulkhead and sort out the pedals. I've finally managed to separate the 'Cross Shaft' and wasn't suprised it was so difficult to drift out - it had been put in dry and had just rusted in solid.

I was lacking a huge amount of clutch and brake fluid. So I topped up and had another look today and the area around the brake master cylinder is damp. The paint was flakey before and it's not going to get much better with fresh fluid pouring all over it! My plan is to rebuild (and possibly replace) both cylinders. I had previously replaced all brake and clutch parts except the clutch pipe and the master cylinders so I guess its about time! I thought I'd also take the time to repaint the bulkhead and sort out the pedals. I've finally managed to separate the 'Cross Shaft' and wasn't suprised it was so difficult to drift out - it had been put in dry and had just rusted in solid.Of course I thought I'd improve things while I'm tinkering. I plan to replace the clutch pipe with a braided flexable version and to paint the finished cylinders black to aid heat dissipation. I have also chucked out the worn out pedal rubbers (60g) and replaced them with griptape. This is the stuff I used on my wakeskates and it's super hardwearing, waterproof and weighs so little I couldn't measure it on the scales! Not the biggest weight saving in the world but it all adds up!

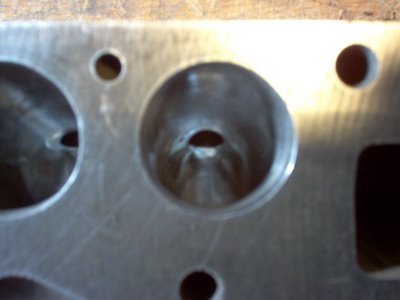

The nearly finished inlet ports looks a whole lot better than they did to start with!

The nearly finished inlet ports looks a whole lot better than they did to start with! And I'm also about halfway through polishing the chambers!

And I'm also about halfway through polishing the chambers!

It drives beautifully and the modifications have made it very different to drive to how it was before in both a good and a bad way! On smooth roads the 380lb springs and AVO dampers mean it handles amazingly and goes exactly where it's pointed without leaning at all, but on bumpy roads it really is spine jarring and it really crashes into potholes. The red Polybushes also transmit much more feedback through the steering and chassis. I can literally feel white lines in the road when I run over them!

It drives beautifully and the modifications have made it very different to drive to how it was before in both a good and a bad way! On smooth roads the 380lb springs and AVO dampers mean it handles amazingly and goes exactly where it's pointed without leaning at all, but on bumpy roads it really is spine jarring and it really crashes into potholes. The red Polybushes also transmit much more feedback through the steering and chassis. I can literally feel white lines in the road when I run over them!  The 12" Mountney steering wheel means I can finally get my legs in properly and the steering dosen't seem to have got noticably heavier. It looks great but I'm having a bit of a job getting the horn push to work! Karl gave it his best go, soldering a wire from the push to the 'pencil connector' (the way recommended by most of the people I asked on the Club Triumph forum) but the pressure of the spring keeps popping the horn push out of the steering wheel so watch this space for a better solution!

The 12" Mountney steering wheel means I can finally get my legs in properly and the steering dosen't seem to have got noticably heavier. It looks great but I'm having a bit of a job getting the horn push to work! Karl gave it his best go, soldering a wire from the push to the 'pencil connector' (the way recommended by most of the people I asked on the Club Triumph forum) but the pressure of the spring keeps popping the horn push out of the steering wheel so watch this space for a better solution!  The exhaust is looking pretty good too! It's not too loud when coasting but has a lovely throaty roar when accelerating hard! When I get round to redoing the mounts I will also move the tailpipe out a bit as my back bumper gets covered in soot around the part where the exhaust exits!

The exhaust is looking pretty good too! It's not too loud when coasting but has a lovely throaty roar when accelerating hard! When I get round to redoing the mounts I will also move the tailpipe out a bit as my back bumper gets covered in soot around the part where the exhaust exits!